One of the beautiful things about brewing is the pleasure of making something manually, in which you put some thought, and that you then can enjoy.

As part of the thought you put into it an understanding of the process and the principles is required.

That understanding needs to be communicated, in order to verify it and also to enrich it against other peoples ideas.

In the case of brewing the process is simple. Yeast, which are unicellular organisms, need to eat to survive, just like us. We eat all sort of different things since we are complex animals, but for a yeast, some sugar, and minimal amounts of protein are enough. The rest they manufacture themselves.

Yeast being very simple they do not have a complex mechanism for eating. They just float in water, in which their nutrients are floating, and the nutrients enter the cell membrane according to a difference in concentrations.

If we were to imagine it in humans, we would be floating in a soup. We would not eat as such: food, drink and air would just enter our bodies and be consumed.

We all know that what we eat produces waste. That is also true for yeast.

The same way the the nutrients are internalised across the membrane, the waste material which are the toxic by-products of transforming the nutrients, are also eliminated across the membrane. As the yeast eats, it grows, just like us. As it grows it creates little yeast cells on the edge of the membrane which when sufficiently big break off and become other yeast cells which then again float in the same nutrient liquid.

If at this stage you have been following, you would have realised that the yeast cells float also in their own waste material. So to bring back our analogy we would be in a soup from which we eat, and at the same time defecate in it. That may seem indeed gross to us, but a yeast being a single cell has no neurons, hence can not develop advanced concepts such as gross.

Most yeasts, if the medium is not refreshed would die due to the waste that they generate, same as we would. However some yeast are resisting to their waste. Some of them are alcohol resistant.

Oh yes, I forgot to mention, yeast eat sugar, but defecate alcohol. Is that not a cool thing?

Yeasts are happy eating and reproducing, eating away as much sugar as they can, and on top of that

they poop alcohol. Which we actually appreciate because of the effects it has on our brains, and our bodies. Yeast as part of their growth also fart, just like we do. We expel methane which is the by-product of some bacteria that lie in our gut. Yeasts expel CO2 which we also appreciate because it tickles our tongues when the bubbles break away from the liquid.

So in effect beer are the left over nutrients that the yeast could not eat, together with what they farted, CO2, and what they pooped. The best thing of it all is that we love what those little yeasts do.

At the end of the day all we aim to do is, make the yeasts happy.

That is provide them with a lot of food so that they eat a lot and poop a lot.

This is obviously a slight simplification, not all the sugars break down equally, and that gives the aromas to the final product. But you do get a pretty good idea of what you drink.

Geek Brewing

We are a bunch of geeks that like beer and have recently started to brew it.

Tuesday, June 21, 2011

Monday, June 20, 2011

Suzanne Lee: Grow your own clothes | Video on TED.com

{EAV_BLOG_VER:27e7de0d1a0d6d66}

Seeing Suzanne Lee: Grow your own clothes | Video on TED.com

I could think of diversifying into making clothes out of beer, or beer out of clothes.

Seeing Suzanne Lee: Grow your own clothes | Video on TED.com

I could think of diversifying into making clothes out of beer, or beer out of clothes.

Saturday, June 18, 2011

Camel Toe

Even without the whole of the automation in place we decided to go ahead and brew from grain.

In all in all it was a good exercise, lots to learn when brewing from grain.

It is indeed in the little details like the mash cycles, and how the grain has to be cracked that you feel that although you are brewing for a year you are still a noob.

We had a guest brewer Bart which has been brewing from grain for quite a while. Thanks to Bart we got some basic tips like the size to which the grain should be milled.

Of course our ultra keg which you have seen the birth of in previous posts, does not have a filter fitted in so in order to avoid the grain from clogging the tap, we had to be creative. Bart proposed to used some panties, which did the trick extremely well. From that you will understand the name of the blog post and hence the beer.

Now nylon panties come usually coloured, and you do not want the colouring to end up in your beer so what do you do: you boil them!

Until they go to the true colour of Nylon, which none of us knew what it was.

The things you learn when you brew beer.

So after that we had the wondrous occupation of stuffing the panties. Sounds dirty I know.

In all in all it was a good exercise, lots to learn when brewing from grain.

It is indeed in the little details like the mash cycles, and how the grain has to be cracked that you feel that although you are brewing for a year you are still a noob.

We had a guest brewer Bart which has been brewing from grain for quite a while. Thanks to Bart we got some basic tips like the size to which the grain should be milled.

|

| Tuning the size of the grain |

Now nylon panties come usually coloured, and you do not want the colouring to end up in your beer so what do you do: you boil them!

|

| Boiling panties, a weird occupation for a bunch of guys. |

Until they go to the true colour of Nylon, which none of us knew what it was.

The things you learn when you brew beer.

|

| Nylon is white, who would have thought that |

|

| Now you know where the name of the beer comes from |

Of course you stuff the panties with the grain and then you have to provide more support. Nylon may be resistant but the last thing you want is the grain all over the place.

So you wrap it in another layer.

|

| Bart, with the improvised grain bag. |

Then the mash can begin.

We used a very simple mash schedule. Which we lifted from here (in Dutch, google translate should do the trick)

|

| Filling in the keg, sensor and resistance in sight. |

We are now ready for the mashing.

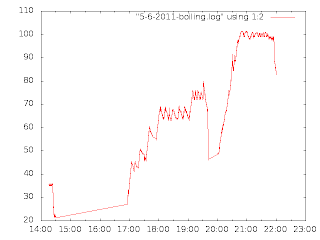

Since the power control is not there yet we decided to monitor the temperature in the usual way and switch on and off by hand. Which gives a peculiar temperature curve. Being lazy we decided to over shoot by 5 degrees and letting cool down, all of that whilst steering by hand.

|

| Temperature graph for CamelToe |

It is pretty clear that the we where a bit lax with the temperature bounds of the mashing which we started around 17:00. The time before that was spent boiling the panties.

By 21:00 the boiling was on and we added just a little bit of hops.

|

| On the boil full hops |

And of course you always reach the glorious moment of pouring it into the fermenter.

We had a bit of a mishap with the wort cooler deciding that it would detach the water outlet, so we had to cool overnight. And luckily my laptop only got a few droplets of water on it.

|

| The final pour |

You can check the see the recipe on Hopville. Right now the beer is fermenting, and should be bottled tomorrow. It did barf a bit and that is what is expected, at the end of the day, that is what yeast does.

I leave you then with another one of the pictures of the event which describes better the atmosphere of the event.

Monday, January 10, 2011

Big Bang the Brew

Shortly before the new year we decided to brew another batch. The purpose was to move towards automating the the brewing and fermentation process. Of course we also try to get more experience about brewing and we aim to go full grain. In order to automate the steeping it is a good idea to move from gas to electric. Its easier to automate the temperature control for the steeping.

So we acquired a 2 KW heating element from our favourite beer brewing supply store. It was then necessary to fit it into the keg. To do that The keg offered a second grind-core concert as a whole was drilled in order to fit the heating element.

|

| Bjorn holding the keg through the drilling. |

|

| Drilling Piet in action. |

|

| The end result. |

Of course the whole was a few millimetres too big and an extra washer had to be made. This was kindly laser cut for us in an adjacent workshop. Also the seal that came with the heating element was to small another one was bought at the local hardware store. the internal diameter of the seal was 31mm instead of 40 but it all assembled to perfection.

The other addition in this brew was the temperature sensor. We bought a usb temperature sensor Just like the one depicted here.

|

| USB temperature sensor |

In the final assembly, already under water we also put the temperature sensor inside a bit of garden hose mainly to prevent it from moving around and touching the heating element as the water started to boil.

|

| Final assembly filled with water and a little hose to shield the sensor |

As for the beer characteristics we decided to do a basic beer too keep things simple you can find the Big Bang Recipe over at hopville.

After boiling for an hour, the beer was cooled and then poured into the fermenter that was previously sanitised. You can see in the next picture the whole assembly with the wort cooler inside the keg and the laptop displaying the temperature readings of the whole session.

And here is the graph for the whole night. A nice feature of the sensor we are using is that it generates a huge outlier value response to the power surge when the power is switched on or off in the heating element. You can see in the graph a -96 value which corresponds to that event. A full data analysis would explain what went on all night with the keg but it will do it more justice if it was done on a separate post.

For some of you the style of the graph will feel familiar. It is indeed gnuplot that produced the graph.

Here is the family picture too dark obviously, but its in the dark that the best beers are brewed.

Monday, December 6, 2010

There are many brews but this is ours

There are many resources about beer brewing in the internet. So why add another one, well because we can, and because we want to share our experiences.

Subscribe to:

Posts (Atom)